The HISTORY

A look at the future

Already in the immediate future new challenges await SEIM world-wide.

To face them, SEIM rearranges the share of the company know-how within it Sales Dept. structure and at the same time reinforces itwith a Team of specialized Sales Engineers. Their high level of professionalism aim to provide quick answers to inquiries and queries from our customers all over the world.

New spaces and new departments for the assembly and testing of custom products.

New tooling machine!

In order to increase the production capacity and support the growing sales, SEIM installs a new robotised work station.

SEIM also achieves a prestigious certification for the Marine Division - the CCS TYPE APPROVAL

A new focus on customers

The renowned reliability of SEIM pumps, unfortunately, can not mean that they are indestructible ... To provide answers to the growing demand for spare parts for SEIM pumps now obsolete and out of catalogue, as well as to provide prompt assistance to the request for specific spare parts, SEIM starts business at the Spare Parts Office. Here, a dedicated Team follows customers from all over the world and quickly provides them with answers.

SEIM achieves prestigious international awards in the Marine sector obtaining:

- LR Quality Assurance Scheme

- BV Mode I.

New machine tools at SEIM! (part 2)

The market demand is constantly expanding and SEIM responds with further investments. Two new CNC machines served by a robotic system allow the production of components in a 24/7 cycle.

SEIM celebrates its first 40 years of activity!

An important goal, a look at the past to review the successes already achieved, a look at the future to look at new horizons and achieve new successes!

The PB Series adds new features and its success grows further.

The PB three screw pump finds development in the cooling lubrication sector in machine tools with a version dedicated to this specific use, and it is immediately successful!

The high reliability of the SEIM product and the extrinsic characteristics in the series of advantages offered against other types of pumps, lead the PB product to be one of the most requested in the production of SEIM.

New spaces at SEIM

The growing demand for finished products requires a new organization of space for the SEIM structure: hence the need to expand its boundaries with the acquisition of the neighboring structure of over 2000 square meters.

The new spaces are used for Logistics and offer opportunities for the installation of new testing areas for custom products SEIM products and for all the tests requiring the presence of inspectors of the Customer, third parties and / or certification bodies.

Certificates: RINA Alternative Testing

New machine tools at SEIM! (part 1)

SEIM's investments to cope the demand of the Markets passes new through production technologies, then the purchase and commissioning of a new CNC machine capable 24/7 production and equipped with an integrated control system of the screws manufactured.

A big step forward in order to produce ever better components: this does not exempt SEIM from the 100% functional testing of the pumps produced, to further grant user’s satisfaction and product reliability.

Among the line-up of SEIM pumps, is added the PB Series: it is specifically designed for applications in the Marine sector, for the pumping of combustible fluids and lubricants.

The PB Series is born with the ABS certification.

Certificates: BUREAU VERITAS Mode II GREEN PASSPORT

The second million SEIM pumps produced is reached!

New partnerships support the growth of SEIM with the opening of local offices of SEIM USA and SEIM GERMANY.

In the Mid-West of the USA, the collaboration of Shanleypump Inc., undertaken by the interest of Larry Shanley Jr. in SEIM since the early 2000s, is affirmed with the creation of SEIM USA.

In Illinois there are: finished products warehouse and spare parts, test benches and assistance offered to cover all the States and Canada.

In Germany, the engineer Lars Kampmeier and his propensity for commercial development given his long experience on the market bring SEIM to a rapid growth thanks to the start of commercial activity under the name SEIM GERMANY UG.

The importance of accurate flow measurement finds the economic and reliable solution in the MPVB Series.

Far East and Sea

After years of collaboration, the structure of SEIM KOREA starts doing business in the Republic of Korea.

The collaboration with a local entrepreneur, the graduated engineer Chan Suk SEO, begun in 2005. It finds its concretization in the definitive affirmation of the SEIM products on the market with the opening of the offices of Seoul and then of Pohang.

In Pohang are located office building with warehouse (a large pumps inventory), test benches and after-sales service. SEIM KOREA provides further impetus to penetrate a demanding market from the point of view of professionalism, service and fast delivery.

SEIM Marine Division is born, specializing in all ship and port applications where pumps are required that are approved by leading international Classification Bodies.

Quality in production also passes through a system equipped with adequate control systems: SEIM equipes with a state-of-the-art 3D metrological system.

Certificates: CTR/RTN

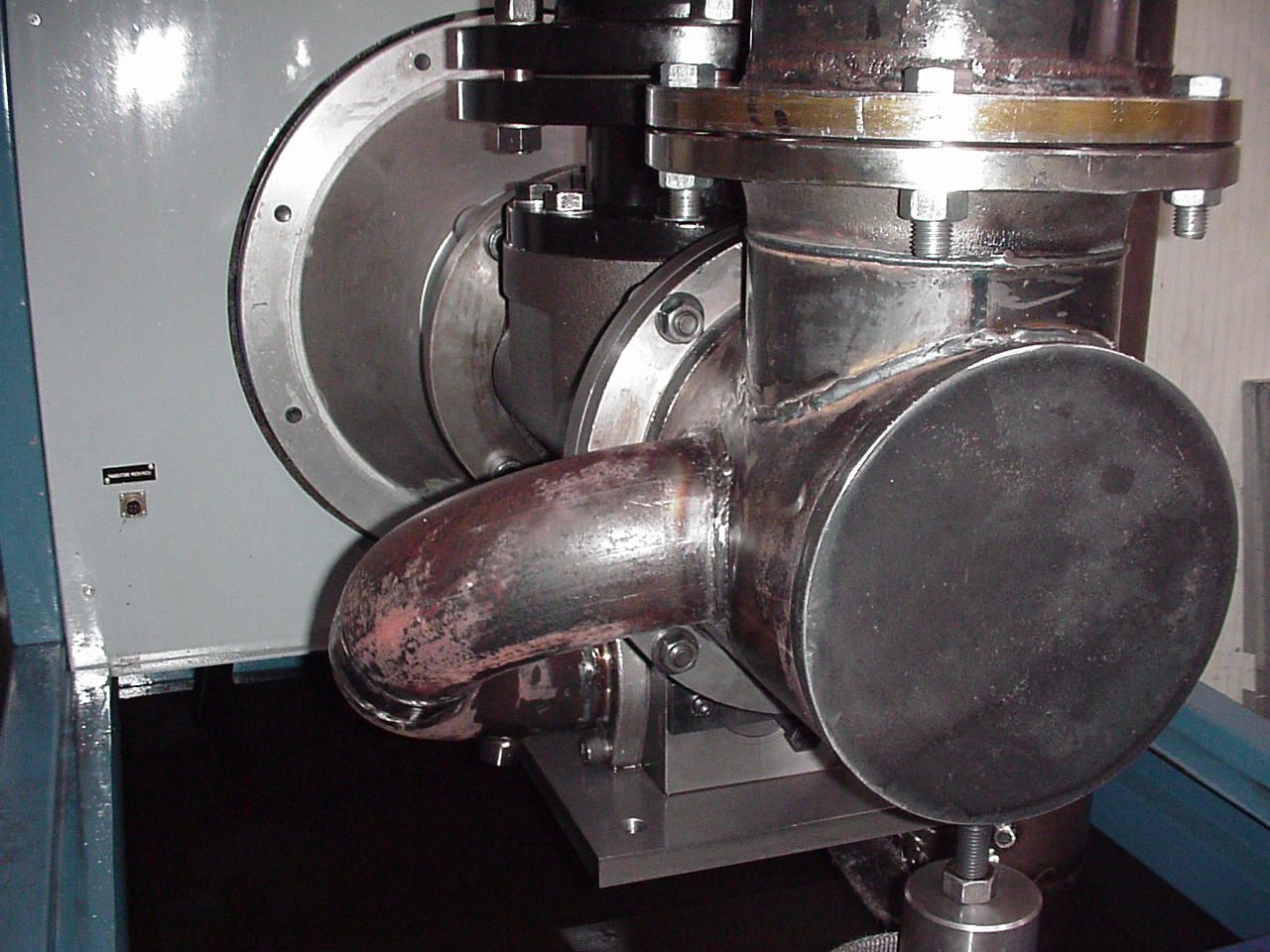

It is the year of SEIM twin-screw pumps

the new twin-screw pumps produced by SEIM find applications where high flow pumps and / or situations are required where the NPSHr represents a challenge.

Both in the version with timing gears, and in its simpler WTG version, SEIM twin-screw pumps have found wide acceptance by the market.

... and double pumping stations.

The most recent Division at SEIM – the Marine Division, achieves the type approval of ABS and begins the production of double pumping stations for fuel supply systems.

Certificates: ABS Type Approval

More room for growth and new goals at the O&G Division

The beginning of the new year sees the expansion of the area owned by SEIM, with the annexation of a neighbor building directly connected to the buildings of the “historic core” (production department and office building).

The new total area passes to about 8,000 square meters.

Continuing in the wake of the success of the pumps meeting the requisites of the API 676, the version of the PCX Series complying with the III ed. is now available.

Top notch performances and further quality guarantees

The SEIM Quality System is certified ISO 9001-2008.

The three screw pump PWO - high-performance series - appears on the market and it becomes immediately successful in the world of cooling lubrication in the machine tool sector and production of mechanical components for the auto motive industry.

Certificates: ISO 9001:2008

For high risk (explosion) areas, to cool oil and high pressure!

SEIM pumps comply with ATEX regulations for zone II, but in 2007 a step forward takes place when some Series obtain the ATEX Ex II 2G T3 / T4 certification.

The NEG series of air-oil heat exchangers is launched on the market and is immediately successful, both in the European and Asian markets, as well as the version approved for use in North America.

The POF Series replaces the previous PF and is widely used in mining and cement works for the hydrostatic bearing lubrication service.

Certificates: ATEX Ex II 2G T3/T4

New answers to new questions

The API676 standard pumps have been SEIM's know-how since the 1990s: the most up-to-date version becomes the PCX Series, complying with the requirements of the API676 II standard.

An epochal overtaking

For the first time in the history of SEIM, the weight of the turnover of the Industry and O & G Divisions exceeds that generated by the LIFT Division.

From then on, the growth of turnover and development in the markets is continuous and the contribution of the elevator sector, while remaining at the level of overall importance, is constantly exceeded by the other specialized Divisions.

... and a new offer to the flow measurement market.

MPVA is the new SEIM screw flow meter, characterized by high precision and reliability.

Oil and Gas

SEIM's know-how is aiming to towards the Power Generation and the petrochemical industry.

The O & G Division develops contacts and the first successes in the Sector are achieved.

The cooling lubrication in machine tools achieves new performance targets with the entry into the catalog of the PO6 Series - high pressure pump for water - oil emulsion featuring top construction characteristics.

To complete the offer to the PO6 pump, are now available the pneumatic control valves VCP and the safety valves for direct mounting on the PO6 pump OUT port, the BVPA Series.

Another step forward in the history of SEIM towards current times

- the Quality System is updated to the ISO9001-2000 standard

- PGA Series lubrication-cooling pumps improve the performance of the previous G4 Series

- The PDA Series - generated by the success of the previous PD, is widely used by OEMs.

Certificates: ISO 9001:2000

Whether large or small flow rate demand, SEIM offers a solution

- PU Series pumps for high flow rates, which implement the performance of the previous T3

- PN pumps, economical and dedicated to OEMs.

A year of big changes at SEIM

- SEIM FRANCE (ESP GROUPE) is the local collaborator for France. His General Manager - Mr. René Radigon, with its long experience deriving from the previous collaboration with SEIM of the company Fluavis, gives great impulse to the French market for SEIM.

- new test benches are installed in production: SEIM has always tested all the pumps produced!

- the winning series of "PX" pumps begins to make its appearance on the markets, the forerunner of SEIM's global success in hydraulic and heavy lubrication.

Diversification also passes through the reinforcement of production capacity

- new CNC machines further extend the M.U. of SEIM

- the pumps for high pressure in the lubricating / cooling machine sector are born, the G4 Series

- high pressure pumps in hydraulic systems (E6 series pumps) come into production

SEIM's great achievements in 1995

- ISO9001 certification attainment

- the first million pumps produced are reached

- Series T3 pumps - production of screw pumps for large flow rates

Certificates: ISO 9001

The growing demand for pumps requires a more structured production lines

The growing demand for pumps requires a more structured production lines at SEIM screw pumps. The answer is to implement the production quality and capability from a few CNCs to a set of new machining centers (characterized by superior performance).

SEIM Catalog now includes pumps that are compliant with API676 standards.

New Headquarters

SEIM moves to the new headquarters in Cusago (Milan): this allows to expand the range of screw pumps to serve different sectors.

The Industry Division is born.

New series of external pumps are added to the catalog and also the first productions of heat exchangers (equipped with SEIM screw pumps).

The foundation

SEIM s.r.l. born from the intuition of its founder, the entrepreneur Mr. Giuseppe Martini, who wants to give an Italian answer to the growing demand for screw pumps for the hydraulic elevators sector. On July 1, 1975 SEIM began its production at the plant located in the west of Milan.

The LIFT Division of SEIM is born, with the production of the S4F Series